About Us

Carlier Plastiques is a European leader in the market of composite panels, located in Calonne-Ricouart in the Hauts-de-France region.

This company was created in 1957 by Charles Carlier, an ambitious young engineer who graduated from one of the best universities in France: Les Arts et Métiers. Charles graduated with a major in plastic materials and wanted to create his own company that would focus on the development and improvement of plastic processing methods.

Since then, Carlier Plastiques continues to offer composite material solutions for products providing excellent quality-to-price ratio.

THE HISTORY OF THE COMPANY

Creation of Carlier Plastiques

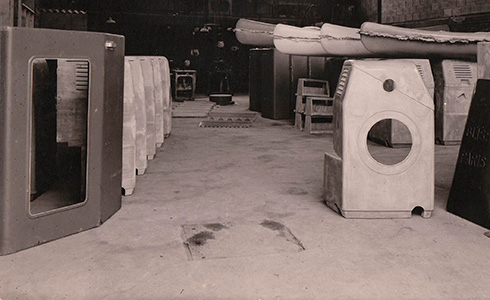

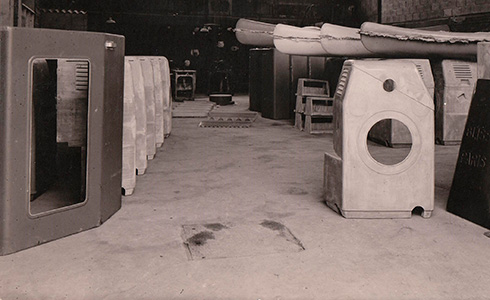

In 1957, Charles Carlier, Arts et Métiers engineer, created his composite parts production company in Calonne-Ricouart in France.

He then expanded his product range with composite tanks.

The First Panels

In 1973, Carlier Plastiques started to supply panels for maritime containers manufactured with our current manual press.

Expansion

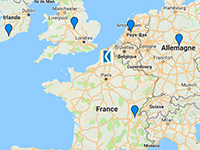

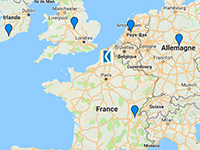

In 1978, Carlier Plastiques expanded its services internationally in Germany, Benelux and then in the United Kingdom.

New production line

Creation of a continuous sandwich panel production line, the first in Europe.

Refocusing of our activity

In 2001, the company refocused on the panel business. Over the years, our panel range has evolved and expanded, now offering the following products: “Panolit, Isolit, Perlit, Nidalit, Lamilit & Floorlit”.

Carlier Plastiques panels are generally used for the construction of various truck and trailer bodies : Bulk heads, side walls, doors, roofs, floors but they can also be used for many other applications …

ISO 9001 certification

In 2005, Carlier Plastiques obtained the ISO 9001 quality certification.

|

|

|

OUR PRODUCTION MEANS :

|

|

DEVELOPMENT :

|

Carlier Plastiques is constantly looking for new materials, new cores, new manufacturing processes, and new skills in the composites sector to increase the features of its products in terms of strength, weight-reduction and insulation. We also carry out various tests in our laboratory such as mechanical resistance measurements and regular audits. |

One of our test machines. |

QUALITY FIRST :

|

As a major part of Carlier Plastiques development, our Quality Policy is an essential tool for our progress, we provide: – A sustainable supply Carlier Plastiques only uses PEFC certified plywood. – Control of raw materials upon receipt. – Recyclable panels. For several years now, our waste has been recycled as CSR (Solid Recovered Fuel).

Download here the ISO 9001 certificate

|

|

About Us

Carlier Plastiques is a European leader in the market of composite panels, located in Calonne-Ricouart in the Hauts-de-France region.

This company was created in 1957 by Charles Carlier, an ambitious young engineer who graduated from one of the best universities in France: Les Arts et Métiers. Charles graduated with a major in plastic materials and wanted to create his own company that would focus on the development and improvement of plastic processing methods.

Since then, Carlier Plastiques continues to offer composite material solutions for products providing excellent quality-to-price ratio.

THE HISTORY OF THE COMPANY

1957 - Creation of Carlier Plastiques

In 1957, Charles Carlier, Arts et Métiers engineer, created his composite parts production company in Calonne-Ricouart in France.

He then expanded his product range with composite tanks.

1973 - The First Panels

In 1973, Carlier Plastiques started to supply panels for maritime containers manufactured with our current manual press.

1978 - Expansion

In 1978, Carlier Plastiques expanded its services internationally in Germany, Benelux and then in the United Kingdom.

1989 - New production line

Creation of a continuous sandwich panel production line, the first in Europe.

2001 - Refocusing of our activity

In 2001, the company refocused on the panel business. Over the years, our panel range has evolved and expanded, now offering the following products: “Panolit, Isolit, Perlit, Nidalit, Lamilit & Floorlit”.

Carlier Plastiques panels are generally used for the construction of various truck and trailer bodies : Bulk heads, side walls, doors, roofs, floors but they can also be used for many other applications …

2005 - ISO 9001 certification

In 2005, Carlier Plastiques obtained the ISO 9001 quality certification.

|

|

|

OUR PRODUCTION MEANS :

- 14,210 m² of workshop on 3.6 hectare site.

- A moulding workshop including :

- A continuous manufacturing press

- A manual press

- Two small presses

- A finishing workshop comprising of :

- Two saws for flat panels

- A manual saw

- A CNC Machine for different tooling services like cuttings,

drillings, rebates, rails…

DEVELOPMENT :

Carlier Plastiques is constantly looking for new materials, new cores, new manufacturing processes, and new skills in the composites sector to increase the features of its products in terms of strength, weight-reduction and insulation.

We also carry out various tests in our laboratory such as mechanical resistance measurements and regular audits.

One of our test machines.

QUALITY FIRST :

As a major part of Carlier Plastiques development, our Quality Policy is an essential tool for our progress, we provide:

– A sustainable supply

Carlier Plastiques only uses PEFC certified plywood.

– Control of raw materials upon receipt.

– Recyclable panels.

For several years now, our waste has been recycled as CSR (Solid Recovered Fuel).

- Carlier Plastiques is certified ISO 9001 and all finished product controls are carried out within the tolerances of the standard NF T 57-950-1 for sandwich panels.

Download here the ISO 9001 certificate