FAQ

YOU WILL FIND OUR FREQUENTLY ASKED QUESTIONS ON THIS PAGE.

Frequently Asked QuestionsHere is non-exhaustive list of our most frequently asked questions. We hope it will help you answer some of your inquiries. If however you do not find the answer to your question(s), feel free to contact us directly by phone, email or using our contact form. |

The inner and outer faces are not identical in terms of aspect and therefore cannot be interchangeable. To recognize the inner side, the panels are delivered with an « INTERIOR SURFACE » label such as below: Plywood panels with a height of more than 2430 mm have an extension piece fitted to achieve the required height and therefore are not symmetrical. To have the extension piece at the top of the panel, the label below is fitted to indicate the top of the panel. It is therefore necessary to respect the mounting direction according to the « TOP » label placed on the panel.

Each panel has an order identification label. It is positioned so that the customer can identify the panel when it is placed flat. This label can be found on either the outside or inside face and on any angle of the panel.

When the panels are manufactured according to the customers’ or to our drawings, these drawings are attached on the outside face of the panels. If it is a drawing from the interior view of the vehicle, the drawing is glued face down to remind you that it is an interior view. In case of doubt, please contact our sales department. 1- Unloading and handling must be carried out with straps crane or vacuum lifters. Straps and suction cups must be in sufficient number and spacing to avoid deformation and/or breakage of the panels. A minimum of 5 straps or 5 suction cups is required for a semi-trailer panel. The straps must not be spaced at more than 2m apart. In the case of strap handling, protective angles must be placed on the edges between the straps and the panel(s). Using metallic chains is forbidden. If you do not have cranes or vacuum cranes, we recommend the following installation:

In all cases of handling and storage, it is important to prevent the panels from being scratched by friction during operations. When handling door panels or front panels, a forklift truck can be used, provided that the lower and upper surfaces of the packages are well protected and that the forks are equipped with protective « socks« , Unprotected forks can damage the surface of the panels. 2- Panel storage should be made in a closed building, ventilated and not humid. Storage of panels outside is not permitted. If, however, you have no other option, you must limit this storage to one week and in this case every precaution should be taken to avoid the risk of water vapour or condensation and therefore moisture ingress. The panels must be stored flat on a horizontal floor and the packages of panels placed on wedges, taking care not to damage the panel surface and spaced at a maximum distance of 1.5 m. Similarly, when stacking several packs of panels vertically, timbers should be placed so as not to create cantilever constraints. When storing panels for a long period of time delivered with a protective adhesive film, it is recommended to remove the film no later than 3 weeks after delivery to avoid any change in colour. Any problem found upon receipt of the products must be mentioned immediately on the waybill. This is the absolute condition for asserting your rights, otherwise the waybill signed without reserves will equal to an acceptance of the goods as they stand, which would make any claim non acceptable. Any damage found on receipt to be due to transport must be reported to the carrier by registered letter within three days of delivery. Any complaint must be sent immediately to Carlier Plastiques to the after-sales service at Panels must be inspected before mounting and all visible problem found must be reported to Carlier Plastiques before use or processing of the panels. Return of panels Any return of panels must be agreed in advance with Carlier Plastiques.

The applicable dimensional tolerances are the standard NFT-57-950-1 of February 2019. In summary:

If you notice a dimensional difference that exceeds the tolerances of the standard, do not hesitate to contact after-sales service at Carlier Plastiques. It should be noted that most of the irregularities found on the surfaces of the panels are aesthetic and do not affect the mechanical strength or integrity of the panel until the laminate coating is broken. According to the February 2019 norm NF T 57-950-1, the panel must be checked before assembly and cutting: vertically, under sufficient daylight, at a distance of 2.5 metres from the panel. If a defect is noticeable under these conditions, the panel is non-compliant, unless the irregularities in appearance are allowed such as the following: On the external face: Visual traces due to the mould, the surface condition of the wood or the junctions of the core elements are allowed. For more details on acceptable irregularities and aspect defects, acceptable or not as a claim, please refer to paragraphs 6.3, 6.4, 6.5 and 6.6 of the norm or contact Mélanie Huchin in case of doubt at +33 3 (0) 21 65 49 23 or by email by sending photos and all information, to On the internal face: Wood knots are allowed. In the event of an incident or accident on a composite panel, it is often possible to repair it. This must be done as soon as possible, as a wound on the surface of the panel may cause water ingress into the panel, which alters the characteristics and prevents any warranty claim from being made. Small scratches or cracks can easily be repaired by cleaning the wound and rework the skin. Larger damage can be repaired using the same method, but does require more time. In case of doubt, the panel manufacturer is available to advise you on the repair method. You will find in the repair guide accessible in PDF in the « FAQ/Downloads » tab, as well as in the standard NF T 57-950 part 3 Sandwich panels for industrial bodies, various repair tips. We are of course available to advise you if necessary. Feel free to call us. Circular saw blades with properly sharpened tungsten carbide inserts should be used. A prior verification of the condition of the blade is essential. In the case of cutting out doors, windows or any other type of openings, care must be taken to ensure that they are watertight so that moisture does not penetrate the inside of the panel. Insulated panels : Attention, in the case of panels of the ISOLIT range (ISS or ISP), there is a risk of delamination if the panel is cut. The risk is lowered significantly if the cut is made by clamping the panel to wooden supports at the area to be cut. If the cutting is to be done without a wooden shim, be careful of the quality of the blade and the speed of the saw. Our panels can be delivered, at an extra cost, with a protective adhesive film especially for coloured panels. We can offer you the option of applying a protective film on the outside face of the panel. This film often prevents damage to the outer surface of the panel, but this does not exempt the bodybuilder from taking all the necessary storage and handling precautions. In case of extended storage (more than 3 weeks), this protective film should be removed to avoid any risk of discoloration of the panel. The moulded edge is coated with laminate when tailor-made. This is possible for ISOLIT panels (ISS and ISP). This implies a tailor-made manufacture, as no further cutting is possible. The painted edge corresponds to the application, after production, of an acrylic emulsion to protect the edge of PANOLIT range panels during transport. Inserts are located in the thickness of the panels. Do not hesitate to contact us for a quote. We will simply need a dimensioned drawing. Our standard colour of manufacture is white RAL 9010, but it is possible to manufacture panels with a coloured gelcoat on the external surface. Carlier Plastique draws your attention to the fact that a coloured gelcoat is not equivalent to paint: it does not have the same visual aspect nor the same duration in time. Carlier Plastiques and gelcoat suppliers do not guarantee the durability of the colour, especially dark colours. The panels can be painted with polyurethane paints. For a high-quality end result, it is essential to comply with the specifications published by paint manufacturers. We would like to draw your attention on the painting of honeycomb panels: given the nature of the core of these panels, painting can increase the « golf ball » effect. Carlier Plastiques will not carry any additional sanding and sealing costs that the customer may decide. We strongly do not recommend dark and metallic paints as they promote increased heating on the panel surface. Carlier Plastiques points out that there may be a possible risk of cracks or blisters caused by the heating of the panel in certain climate circumstances. We do not take responsibility for the appearance of such defects. For a high-quality end result, it is essential to comply with the specifications published by paint manufacturers. It is always necessary to check with the decor supplier to ensure that the adhesive decals are suitable for the composite panels supplied by Carlier Plastiques. It is desirable to comply with its requirements for installation and durability. The dark colour of adhesive decors can lead to the same defects as mentioned above for dark paints. |

||||||||||||||||||

Frequently Asked Questions

- Q1: How can I differentiate the inner side from the outer side?

- Q2: How do I handle and store the panels?

- Q3 : My panels arrived damaged. What should I do?

- Q4: My panels are not the right dimensions. What should I do?

- Q5: My panel has a defect, what should I do?

- Q6 : My panels are damaged. How can I repair them?

- Q7 : How do I cut the panels ?

- Q8 : Can the panels be delivered with a protective film?

- Q9: What is the difference between a moulded edge and a painted edge ?

- Q10 : What are the types of inserts that can be put in the panels ?

- Q11: I need a panel with a colour other than the usual white. How should I

proceed? - Q12: How do I paint the panels?

- Q13: Can I stick adhesive decals on the panels?

The inner and outer faces are not identical in terms of aspect and therefore cannot be interchangeable.

To recognize the inner side, the panels are delivered with an « INTERIOR SURFACE » label such as below:

Plywood panels with a height of more than 2430 mm have an extension piece fitted to achieve the required height and therefore are not symmetrical.

To have the extension piece at the top of the panel, the label below is fitted to indicate the top of the panel. It is therefore necessary to respect the mounting direction according to the « TOP » label placed on the panel.

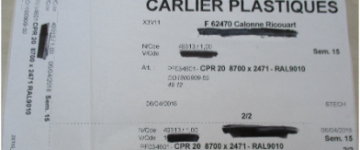

Each panel has an order identification label.

It is positioned so that the customer can identify the panel when it is placed flat. This label can be found on either the outside or inside face and on any angle of the panel.

When the panels are manufactured according to the customers’ or to our drawings, these drawings are attached on the outside face of the panels.

If it is a drawing from the interior view of the vehicle, the drawing is glued face down to remind you that it is an interior view.

In case of doubt, please contact our sales department.

1- Unloading and handling must be carried out with straps crane or vacuum lifters. Straps and suction cups must be in sufficient number and spacing to avoid deformation and/or breakage of the panels. A minimum of 5 straps or 5 suction cups is required for a semi-trailer panel. The straps must not be spaced at more than 2m apart. In the case of strap handling, protective angles must be placed on the edges between the straps and the panel(s). Using metallic chains is forbidden.

If you do not have cranes or vacuum cranes, we recommend the following installation:

|

|

In all cases of handling and storage, it is important to prevent the panels from being scratched by friction during operations.

When handling door panels or front panels, a forklift truck can be used, provided that the lower and upper surfaces of the packages are well protected and that the forks are equipped with protective « socks« , Unprotected forks can damage the surface of the panels.

2- Panel storage should be made in a closed building, ventilated and not humid. Storage of panels outside is not permitted. If, however, you have no other option, you must limit this storage to one week and in this case every precaution should be taken to avoid the risk of water vapour or condensation and therefore moisture ingress.

The panels must be stored flat on a horizontal floor and the packages of panels placed on wedges, taking care not to damage the panel surface and spaced at a maximum distance of 1.5 m. Similarly, when stacking several packs of panels vertically, timbers should be placed so as not to create cantilever constraints.

When storing panels for a long period of time delivered with a protective adhesive film, it is recommended to remove the film no later than 3 weeks after delivery to avoid any change in colour.

Any problem found upon receipt of the products must be mentioned immediately on the waybill. This is the absolute condition for asserting your rights, otherwise the waybill signed without reserves will equal to an acceptance of the goods as they stand, which would make any claim non acceptable.

Any damage found on receipt to be due to transport must be reported to the carrier by registered letter within three days of delivery.

Any complaint must be sent immediately to Carlier Plastiques to the after-sales service at

Panels must be inspected before mounting and all visible problem found must be reported to Carlier Plastiques before use or processing of the panels.

Return of panels

Any return of panels must be agreed in advance with Carlier Plastiques.

To do this, please contact Carlier Plastiques and send photos with a minimum resolution of 500 KB which is essential for an objective analysis.

- Panels returned to the manufacturer must be handled, stored, protected and loaded with the same care as a delivered panel. They must also be identified, ideally with the Carlier Plastiques’ label containing the order number.

- Any deterioration on your part or during transport would in fact prevent our expertise, and at the same time a possible handling of the claim.

The applicable dimensional tolerances are the standard NFT-57-950-1 of February 2019.

Please check that the received dimensions are part of the standard’s tolerances.

In summary:

| Length | +/- 3 mm | If L < 3 m |

| +/- 5 mm | If L > 3m | |

| Width | +/- 3 mm | |

| Thickness | +/- 1 mm | Non isolating core panels |

| +/- 2 mm | Isolating core panels | |

| Diagonals | 6 mm | |

If you notice a dimensional difference that exceeds the tolerances of the standard, do not hesitate to contact after-sales service at Carlier Plastiques.

It should be noted that most of the irregularities found on the surfaces of the panels are aesthetic and do not affect the mechanical strength or integrity of the panel until the laminate coating is broken.

According to the February 2019 norm NF T 57-950-1, the panel must be checked before assembly and cutting: vertically, under sufficient daylight, at a distance of 2.5 metres from the panel.

If a defect is noticeable under these conditions, the panel is non-compliant, unless the irregularities in appearance are allowed such as the following:

On the external face:

Visual traces due to the mould, the surface condition of the wood or the junctions of the core elements are allowed.

As an exception, any aspect defect occurring within 50 mm of the edge of the panel is allowed.

For more details on acceptable irregularities and aspect defects, acceptable or not as a claim, please refer to paragraphs 6.3, 6.4, 6.5 and 6.6 of the norm or contact Mélanie Huchin in case of doubt at +33 3 (0) 21 65 49 23 or by email by sending photos and all information, to

On the internal face:

Wood knots are allowed.

For more information, please refer to paragraph 6.4 of the standard.

In the event of an incident or accident on a composite panel, it is often possible to repair it. This must be done as soon as possible, as a wound on the surface of the panel may cause water ingress into the panel, which alters the characteristics and prevents any warranty claim from being made.

Small scratches or cracks can easily be repaired by cleaning the wound and rework the skin.

Larger damage can be repaired using the same method, but does require more time.

In case of doubt, the panel manufacturer is available to advise you on the repair method.

We also offer repair kits upon request.

You will find in the repair guide accessible in PDF in the « FAQ/Downloads » tab, as well as in the standard NF T 57-950 part 3 Sandwich panels for industrial bodies, various repair tips.

We are of course available to advise you if necessary. Feel free to call us.

Circular saw blades with properly sharpened tungsten carbide inserts should be used. A prior verification of the condition of the blade is essential.

In all cases, the operating instructions of the cutting tool manufacturers must be observed, particularly with regard to the number and spacing of teeth and rotation speed.

In the case of cutting out doors, windows or any other type of openings, care must be taken to ensure that they are watertight so that moisture does not penetrate the inside of the panel.

Insulated panels :

Attention, in the case of panels of the ISOLIT range (ISS or ISP), there is a risk of delamination if the panel is cut. The risk is lowered significantly if the cut is made by clamping the panel to wooden supports at the area to be cut.

If the cutting is to be done without a wooden shim, be careful of the quality of the blade and the speed of the saw.

After cutting, inspect the edge of the panel thoroughly and if it comes off, repair immediately with polyurethane resin or glue.

Our panels can be delivered, at an extra cost, with a protective adhesive film especially for coloured panels.

We can offer you the option of applying a protective film on the outside face of the panel. This film often prevents damage to the outer surface of the panel, but this does not exempt the bodybuilder from taking all the necessary storage and handling precautions.

In case of extended storage (more than 3 weeks), this protective film should be removed to avoid any risk of discoloration of the panel.

If this should happen, however, cleaning the panel with an acetone solvent often reduces this discolouration.

The moulded edge is coated with laminate when tailor-made. This is possible for ISOLIT panels (ISS and ISP). This implies a tailor-made manufacture, as no further cutting is possible.

The painted edge corresponds to the application, after production, of an acrylic emulsion to protect the edge of PANOLIT range panels during transport.

Be careful, this emulsion does not constitute a complete waterproofing of the edges during the life of the panel.

Inserts are located in the thickness of the panels.

Some examples: aluminium or PVC pipes, or wooden shims in ISOLIT panels, or even steel plates under the coating of plywood or peripheral wood.

Do not hesitate to contact us for a quote. We will simply need a dimensioned drawing.

Our standard colour of manufacture is white RAL 9010, but it is possible to manufacture panels with a coloured gelcoat on the external surface.

All colours of the RAL colour chart are available. For any other specific colour, we will match it on the basis of a sample you provide us.

We will send you a sample panel for you to accept the obtained colour.

It takes about 3 to 4 weeks to manufacture a countertyping.

After your written acceptance, we will begin the production.

Carlier Plastique draws your attention to the fact that a coloured gelcoat is not equivalent to paint: it does not have the same visual aspect nor the same duration in time. Carlier Plastiques and gelcoat suppliers do not guarantee the durability of the colour, especially dark colours.

Carlier Plastiques declines all responsibility in this case.

The panels can be painted with polyurethane paints.

For details of implementation, we invite you to consult our user’s guide.

For a high-quality end result, it is essential to comply with the specifications published by paint manufacturers.

Paint suppliers are generally well aware of the precautions to be taken when painting composite panels and can provide useful advice.

We would like to draw your attention on the painting of honeycomb panels: given the nature of the core of these panels, painting can increase the « golf ball » effect. Carlier Plastiques will not carry any additional sanding and sealing costs that the customer may decide.

We strongly do not recommend dark and metallic paints as they promote increased heating on the panel surface. Carlier Plastiques points out that there may be a possible risk of cracks or blisters caused by the heating of the panel in certain climate circumstances. We do not take responsibility for the appearance of such defects.

For a high-quality end result, it is essential to comply with the specifications published by paint manufacturers.

It is always necessary to check with the decor supplier to ensure that the adhesive decals are suitable for the composite panels supplied by Carlier Plastiques. It is desirable to comply with its requirements for installation and durability.

The dark colour of adhesive decors can lead to the same defects as mentioned above for dark paints.